I’ve been trying to determine the best feed rate for cutting MDF on my Shapeoko CNC router with a 1/4-inch bit. The manufacturer’s recommendation is very conservative and slow, and I don’t trust the other recommendations I’ve found. So I decided to cut a large number of identical 2D pockets at different speeds to determine for myself what the best feed rate is for this kind of operation.… Read the rest

Fusion 360

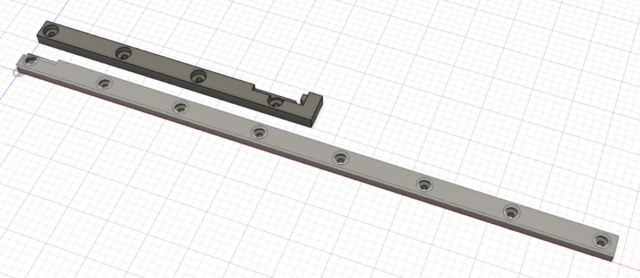

Myers Shapeoko Fence – Fusion 360 Remix

Like many, I’m using the wasteboard, fence and cam clamps that Ben Myers designed for the Shapeoko CNC router. They are excellent and I’ve learned a lot from his many CNC tutorials, so I’ve purchased them all from his Etsy store. Unfortunately, the XL size fence file seems to contain a mistake.… Read the rest