I needed to cut a piece of glass tube to a certain length and this is how I did it using my mini-lathe, an inexpensive diamond blade, some masking tape and WD-40.

I needed to cut a piece of glass tube to a certain length and this is how I did it using my mini-lathe, an inexpensive diamond blade, some masking tape and WD-40.

The Stirling Engine I’m building uses a glass tube for the power cylinder. It calls for one with an outside diameter of 16 mm and a length of 26 mm (1.02-inches), although those dimensions are not critical. I thought I’d have to order a tube with the right diameter but I got lucky and quickly found a package of three 16 mm test tubes in the science kit section of our local Hobby Lobby store. They cost $3.99.

I found all kinds of techniques on the Internet for cutting glass tubes and bottles. One, which I’ll call the flaming string method, didn’t look like it would create the smooth even edge that I wanted. Another video showed how to cut tubing by scoring it part way around with a carbide tool, putting a drop of water on the scratch and then pressing a red hot glass rod into the scratch. That seemed to neatly break the tube, but I didn’t have a glass rod that I could heat up. Others suggested cutting it with a diamond blade and I happened to have one of those.

The blade that I used was from a set of Dremel-size diamond blades that I bought a while ago at my local Harbor Freight for only three or four dollars. They came with a mandrel which I was able to clamp in one of the tool holders for my quick-change tool post.

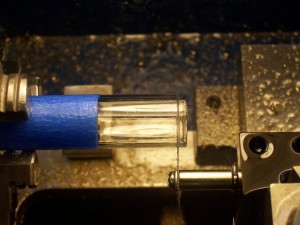

The test tube fit perfectly, and I mean perfectly, in the center hole of my three-jaw chuck. Any bigger and it would not have fit. To ensure that the tube wouldn’t slip while cutting I put some masking tape around it and just barely tightened the jaws. The test tube had a lip on it that would interfere with the piston so the first photo shows me cutting it off.

I set the lathe in high gear and turned the speed control to almost maximum and then very, very slowly advanced the cross slide. Water is usually used as a lubricant and coolant when cutting glass with a diamond blade but I didn’t want my lathe to get rusty, so I used a squirt bottle filled with WD-40. It didn’t require much and afterward a paper towel soaked most of it up.

To be safe, I wore a face shield and I recommend that you do the same.

The cut edge was pretty smooth but I tried to make it even better by using the side of the blade to grind the edge. The second cut I made left an even smoother edge so I left it alone. I have a small diamond sharpener that I use to hone cutting edges and if I were to do this again I would probably try to use it like a lathe file to slightly round the edge of the rim that will be exposed when the engine is assembled.

After I cut my tube and wrote this article I learned about some other ways to cut glass. There’s one I’d like to tell you about because it looks like it’s an easy and reliable way to cut a glass cylinder that is too big too be held in a lathe chuck.

The author uses it to make drinking glasses from bottles. He gets smooth even rims by evenly scoring the bottle and then heating it with a torch just above the line to get it to break there. He then goes on to tell you how you can round and polish the edges.

The only problem with his article is that he talks about the importance of accurately scoring the bottle, but he doesn’t really provide any details about how to do that, other than telling you to buy an inexpensive commercial jig or make one yourself. So I’d like to suggest mounting a glass cutter on a height gage type device and then turning the bottle against it while they’re on a surface plate.

You can find the article here.

Rob