This excellent article was written by Bob Bickerton, a new contributor to Machinistblog.com. It was originally published to the files section of the Yahoo 7x12minilathe discussion group.

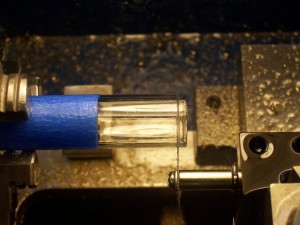

The slowest feed rate on the Mini-lathe is about .004 in/revolution. This is fine for many applications but when you want a nice, smooth turned finish the slowest rate isn’t slow enough. … Read the rest