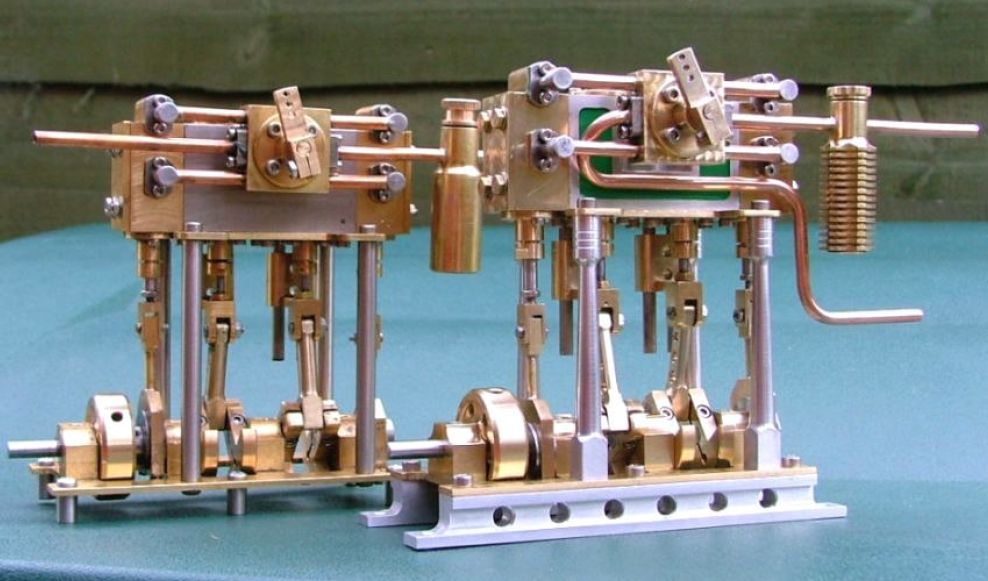

Jan Ridders’ Flame Eater “Marc”

Jan Ridders recently updated his plans for a vertical flame eater engine that he originally made in 2003 as a birthday present for his son Marc. He made a number of improvements and redrew the plans using a CAD program. Jan says this engine is “more forceful and noisy” than his Stirling engine models.… Read the rest