This article describes how I made two round disks on my lathe out of sheet metal that was too thin to be held in a lathe chuck. I also could not use a mandrel because one of the disks was not going to have a hole drilled through its center. The two disks were made from .073-inch thick aluminum sheet metal and are about 5-inches in diameter. … Read the rest

Tools

Make or Buy a Power Feed for your Mini-Mill

I took a couple of machine shop classes and got spoiled by the X-axis power feeds on the Bridgeport mills. Ever since then I have thought about adding one to my Harbor Freight Mini-Mill (Sieg X2).

I took a couple of machine shop classes and got spoiled by the X-axis power feeds on the Bridgeport mills. Ever since then I have thought about adding one to my Harbor Freight Mini-Mill (Sieg X2).

Beside reducing wear and tear on your arm and the boredom of turning and turning and turning a wheel, a power feed can produce a better finish on your parts because it moves the table at a more uniform speed than you probably can. … Read the rest

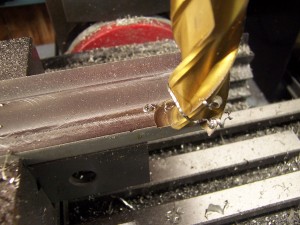

Clamping Thin Work on the Mill – Two Methods

I recently needed to mill down the thickness of a 7-inch long piece of steel from .25-inches to .20-inches. As the metal became thinner I started getting chatter and a bad finish on the ends because they were not being supported enough by my 3.5-inch wide precision screwless vise and 6-inch parallels.… Read the rest

The Mini-Mill Head Drop Problem

A problem with the Sieg X2 mini-mill [HF 44991, Grizzly G8689, Micro-Mark & others] is that the head can suddenly drop down while you’re milling. Everything will seem fine until the head suddenly drops a bit, which causes the end mill to try to cut too much metal at once, causing the table to start shaking as much as the play in the gibs allows. … Read the rest