Dean William’s Web Site

I recently added Dean William’s web site to our list of “Featured Websites,” which you can find on the right sidebar. It’s a short, somewhat exclusive list, which should give you an idea of how impressed I am with it.

I recently added Dean William’s web site to our list of “Featured Websites,” which you can find on the right sidebar. It’s a short, somewhat exclusive list, which should give you an idea of how impressed I am with it.

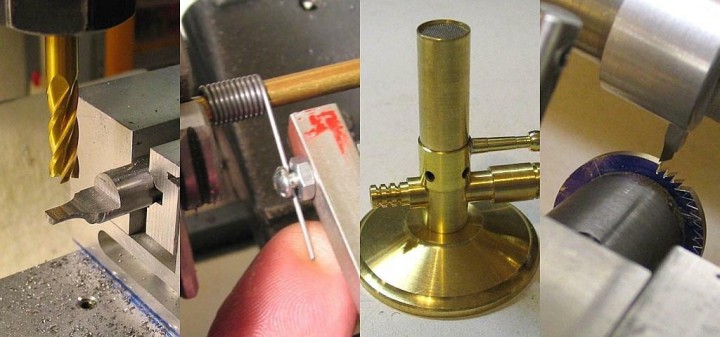

Dean is an excellent photographer and he’s created quite a few photo essays and tutorials on a wide variety of topics. … Read the rest