I took a week of vacation time just to work on my Solsylva CNC router. My goal was to spend at least 10 hours a day on it and try to get it finished. I had a very productive week but I spent most of it working on other things instead. For example, I spent parts of four days getting work done on my car because I usually have to rent one or take a vacation day if it needs service that has to be done during the day. My Camry got new tires, a bad wheel bearing replaced and a front end alignment. I also tried to get a minor EVAP (emissions) problem fixed at another shop but I got ripped off. I didn’t find out until it was too late that the dozens of very positive Google and Yahoo reviews they had were fake.

I also spent about eight hours cleaning up my desk. I can’t stand it when it gets real messy and it had acquired a mountain of paper because I’ve been extremely busy this summer. Some of that time was spent calling up companies and asking them to take my name off their mailing lists. I am amazed at how many of them will send you a monthly or quarterly catalog for years even you’ve never bought anything from them or you’ve maybe placed one small order.

We also had our driveway repaved because the one we had put in about eight years ago developed deep ruts where my wife parks her car. I didn’t want to have it done during my vacation but I’d been trying off and on for a year to get it repaired. I’d called at least four other companies (some more than once) and none of them showed up to give me an estimate. I finally found a one that promptly gave me one and provided good references too. So I wasn’t going to make them wait when the weather finally dried up enough for them to pave it.

Getting the driveway done hurt my productivity for much of the week. I have so many tools in my small garage workshop that I’ve had to put most of the bigger ones on wheels so I can push them out in the driveway when I need more room to work. I couldn’t do that because of the new driveway and that made it much more difficult to paint my router and its stand.

Painting has been holding up progress on my CNC router

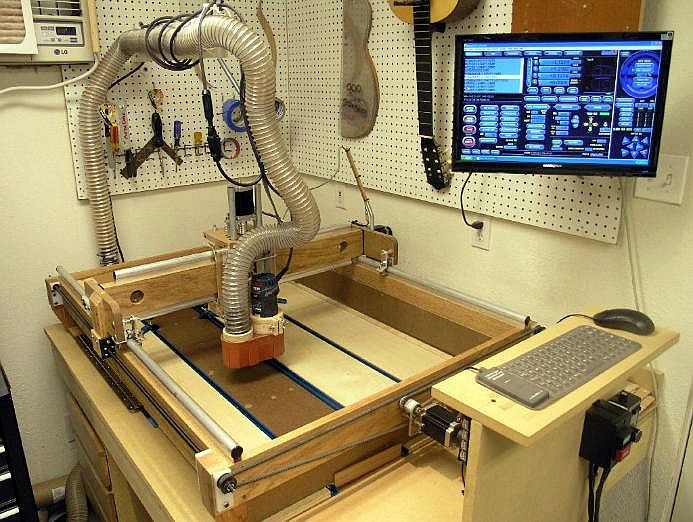

Painting has frequently held up my progress and if I could do it over again I’d probably stain my router’s wooden parts like Don Druckenbrodt did. One reason is my tendency to be a perfectionist. I have it well under control most of the time but I struggle with it when I do painting, trim carpentry and some other tasks where appearance is important (or I think it is). And I’ve been trying to do an especially good job on my CNC router because pictures of it are going to be on this web site and I’ll probably be taking it to some shows and workshops.

I always seem to spend too much time sanding and fixing imperfections in wood, which is why I don’t do much woodworking anymore. I enjoy cutting and fitting the pieces together but I hate applying a finish unless it’s a simple project that just needs a little sanding and a few coats of Tung oil. The metal parts I make in my home machine shop often don’t a require a finish and it’s usually pretty quick and easy to apply one if they do. It usually involves just a little polishing, often with a Scotch-Brite pad, or a quick coat of paint from a spray can.

I don’t like Glidden’s Trim and Door Paint

I also chose the wrong paint and because of that I had to sand down my original paint job on both the router table and its stand and then repaint them. I’m about to do it again to the table but this time I’m going use a different brand of paint.

I was originally going to use Rustoleum enamel which sells for about $9 per quart. But I wasn’t real happy with its durability the last time I used it on wood. So I looked around Home Depot and found Glidden’s “Trim and Door Paint.” It cost twice as much but I decided to try it because it’s a “new” oil-based “gel” paint that is suppose to dry without brush marks or drips. I won’t bore you with the details, unless you want to hear them, but I got a lot of brush marks and runs even though I carefully followed the directions on the can and watched the instructional videos on YouTube. I blamed myself after my first try but after my second try I decided it was the paint.

It also took Home Depot more than two months to get me the “Rich Blue” I wanted. Glidden’s Trim and Door paint can’t be tinted and the color I wanted was one of two they don’t stock even though they advertise them. To be fair, they did try hard to get me the paint. I ended up having to special order six cans and then they refunded the cost of the five I didn’t need.

Other things also interfered with my original plans but I’m not really complaining. I had a very productive week and I got a lot of important things done. The router just wasn’t one of them.

I looking for help how to built homemade cnc. also

as plan , software,and other material. please

thank you