I’m a believer. As a new guy I totally sucked at grinding lathe tools. It’s almost painful to admit how many stubby, misshapen, multi-faceted, overheated and just plain ugly lathe tools I made back then. The amazing thing is that some of those tools actually worked as well as the pre-ground tools that came with my lathe. … Read the rest

I’m a believer. As a new guy I totally sucked at grinding lathe tools. It’s almost painful to admit how many stubby, misshapen, multi-faceted, overheated and just plain ugly lathe tools I made back then. The amazing thing is that some of those tools actually worked as well as the pre-ground tools that came with my lathe. … Read the rest

Tools

Modifying a Craftsman 2 X 42-inch Belt Sander For Tool Grinding

The Craftsman 2 X 42-inch belt sander is a very good general purpose belt sander. With its 1/2 HP motor it can handle most light duty work in the shop, including grinding lathe tools for both metal and wood lathes. This grinder allows for very fast belt changes, tracks well with a simple adjustment and has enough power to grind tools without overheating or bogging down. … Read the rest

The Craftsman 2 X 42-inch belt sander is a very good general purpose belt sander. With its 1/2 HP motor it can handle most light duty work in the shop, including grinding lathe tools for both metal and wood lathes. This grinder allows for very fast belt changes, tracks well with a simple adjustment and has enough power to grind tools without overheating or bogging down. … Read the rest

HSS Indexable Inserts

It’s not obvious at first but this video is about the Arthur R. Warner Company’s HSS indexable inserts. After seeing it I’ve decided that I would really like to give them a try. I know you can get a better finish with HSS bits but I don’t like having to stop to sharpen them. … Read the rest

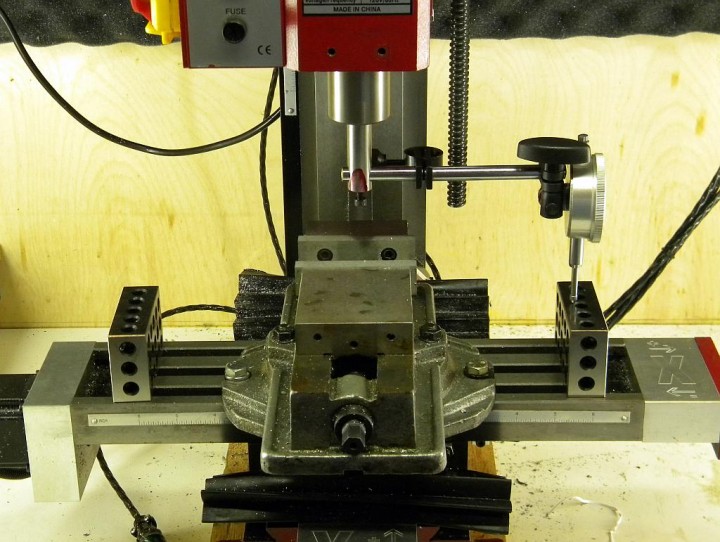

How I tram my mini-mill

This is how I tram my mini-mill. I think the method I use is fairly common, although I may use slightly different equipment than others. There are other ways of doing it and some people have strong opinions about which way is best. I’ve included links at the bottom to some interesting discussions I found if you would like to learn more. … Read the rest

This is how I tram my mini-mill. I think the method I use is fairly common, although I may use slightly different equipment than others. There are other ways of doing it and some people have strong opinions about which way is best. I’ve included links at the bottom to some interesting discussions I found if you would like to learn more. … Read the rest