I bought an old Federal dial indicator from a retired machinist that had a big flat donut-shaped magnet glued on its back. I almost passed it up because it was kind of ugly, but it has turned out to be one of the most useful tools in my workshop. It is particularly useful for adjusting the Z-axis height on my Harbor Freight mini-mill.… Read the rest

I bought an old Federal dial indicator from a retired machinist that had a big flat donut-shaped magnet glued on its back. I almost passed it up because it was kind of ugly, but it has turned out to be one of the most useful tools in my workshop. It is particularly useful for adjusting the Z-axis height on my Harbor Freight mini-mill.… Read the rest

Mods

New V-belt makes speed changes easier

Changing the spindle speed of your Harbor Freight 8×12 or Lathemaster 8×14 lathe will probably be easier if you replace the factory belt with a size 3L300, which you can buy at most auto parts stores for about $5. The original is so tight that changing the spindle speed by moving it to a different set of pulleys can be an unpleasant chore. … Read the rest

Changing the spindle speed of your Harbor Freight 8×12 or Lathemaster 8×14 lathe will probably be easier if you replace the factory belt with a size 3L300, which you can buy at most auto parts stores for about $5. The original is so tight that changing the spindle speed by moving it to a different set of pulleys can be an unpleasant chore. … Read the rest

Carriage Lock Modification for 8×12 or 8×14 Lathe

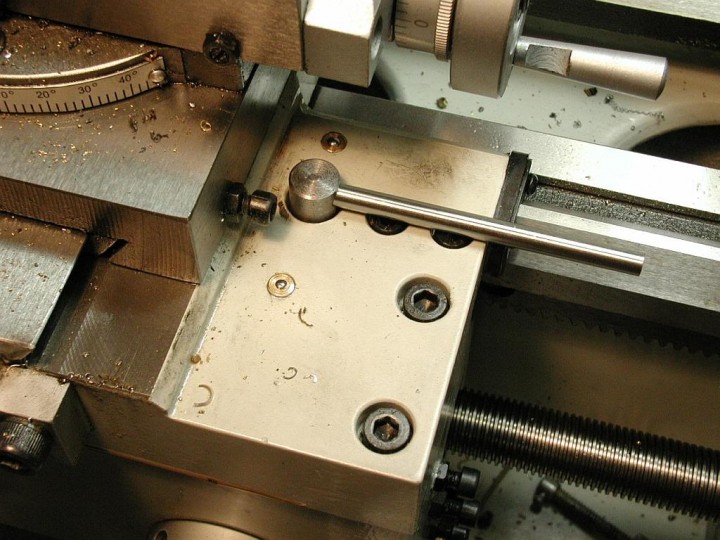

This is Steve Shyver’s carriage lock modification for a Harbor Freight 8×12 or Lathemaster 8×14 lathe (both lathes are the same size if measured the same way). His handle replaces the easy-to-misplace hex wrench that comes with the lathe. Its longer length also makes it easier to turn.

This is Steve Shyver’s carriage lock modification for a Harbor Freight 8×12 or Lathemaster 8×14 lathe (both lathes are the same size if measured the same way). His handle replaces the easy-to-misplace hex wrench that comes with the lathe. Its longer length also makes it easier to turn.

Steve made it using a M8 stainless steel cap screw with a press-on cap he fabricated. … Read the rest

4×6 Bandsaw Cart

This is the roll-around stand I made for my late 80’s Taiwan-made 4×6 bandsaw, which is almost identical to the one Harbor Freight sells. It uses a Harbor Freight 3-shelf service cart with the top shelf turned upside down. I was a little worried about it being top-heavy so I replaced the original 5-inch casters with 3-inch ones mounted on outriggers made from pressure-treated 2x6s. … Read the rest

This is the roll-around stand I made for my late 80’s Taiwan-made 4×6 bandsaw, which is almost identical to the one Harbor Freight sells. It uses a Harbor Freight 3-shelf service cart with the top shelf turned upside down. I was a little worried about it being top-heavy so I replaced the original 5-inch casters with 3-inch ones mounted on outriggers made from pressure-treated 2x6s. … Read the rest